Aluminium Alloy Casting Granule Machine

Introduction

Aluminum alloy casting granule machine

Equipment ApplicationÔľö

Aluminum alloy casting granule machine is used for automatic control in the production of various shapes of aluminum granule, this machine can meet the requirements of continuous production per day 24 hours.

Craft Process:

Liquid aluminum was injection in the package and split evenly into the aluminum grain mould with splitter plate system.Then the water spray proceeds cooling on aluminum particles and makes it consolidation forming.

Equipment Features:

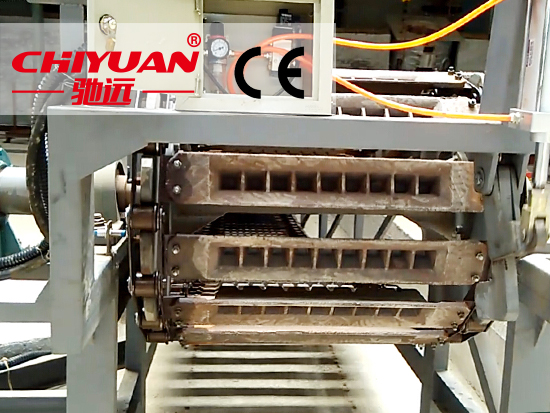

Casting machine adopts straight chain movement,aluminum mould manufactured with globular graphite cast iron,driving part adopts frequency control of motor speed, motor power 5.5 KW,stable operation,power is enough.Demoulding adopts pneumatic hammer,demoulding highly.

Equipment Composition:

Casting machine mainly include the frame part, drive part, transmission part, mould parts, shunt parts, vibration and cooling part.

Technical Parameter:

Equipment ApplicationÔľö

Aluminum alloy casting granule machine is used for automatic control in the production of various shapes of aluminum granule, this machine can meet the requirements of continuous production per day 24 hours.

Craft Process:

Liquid aluminum was injection in the package and split evenly into the aluminum grain mould with splitter plate system.Then the water spray proceeds cooling on aluminum particles and makes it consolidation forming.

Equipment Features:

Casting machine adopts straight chain movement,aluminum mould manufactured with globular graphite cast iron,driving part adopts frequency control of motor speed, motor power 5.5 KW,stable operation,power is enough.Demoulding adopts pneumatic hammer,demoulding highly.

Equipment Composition:

Casting machine mainly include the frame part, drive part, transmission part, mould parts, shunt parts, vibration and cooling part.

Technical Parameter:

| motor power | Mainframe: 5.5KW, auxiliary engine :0.25KW |

| running speed | 0-3.04m/min,0-17 mould min |

| production capacity | 1-1.5t/h |

| Casting way | Automatic Dispensing |

| Cooling way | water cooling |

| electrical requirement | 380V/3 /50HZ |